During the use of security equipment, various problems will appear from time to time, causing unnecessary trouble for us. We need to regularly check and protect each device and line. Such as: lines, alarm equipment, monitoring software, hard disk video recorder equipment, etc.

The precautions for the daily maintenance and maintenance of security monitoring equipment of Kunshan Monitoring and Installation Company are as follows:

1. Detection of alarm signal lines, video signal lines, and camera pan/tilt control lines, troubleshooting, and danger investigation.

2. Detection of solder joints of all interfaces and line interfaces, replacement of video heads, etc.

3. Lens arrangement of the front-end camera of the monitoring system, equipment dust removal, orientation adjustment, equipment repair and replacement, troubleshooting, etc.

4. Detection of dual-detection detectors, adjustment of exploration orientation, repair and replacement of detectors, and troubleshooting.

5. Detection of alarm host and its subordinate equipment, equipment dust removal, defense zone adjustment, fault sweeping, etc.

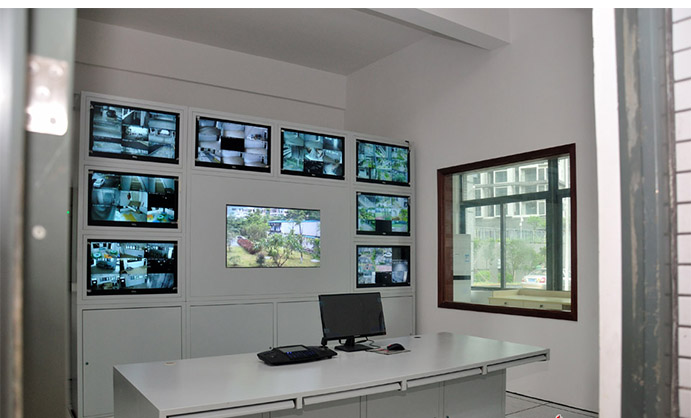

6. Monitor host equipment detection, equipment dust removal, system protection, equipment protection, system expansion, and troubleshooting.

7. Monitoring software detection, software upgrade, software protection, data backup, troubleshooting, etc.

8. System data backup status.

Inspection service

1. Dust and tidy up the equipment every two quarters, clean up the dust exposed by the monitoring equipment, remove the cameras, protective covers and other components completely, blow and dust them, and then wipe the lenses with anhydrous alcohol cotton to make the adjustment clear. To avoid dust inhalation into the body of the monitoring equipment due to factors such as machine operation and static electricity, to ensure the normal operation of the machine. Check the monitoring equipment room ventilation, heat dissipation, dust cleaning, power supply and other equipment together.

2. According to the operation instructions of each part of the security monitoring system, test its technical parameters and the quality of the transmission line of the monitoring system every two quarters, deal with the danger of failure, help the monitoring supervisor to set various data such as the use level, and ensure that each part The equipment has excellent functions and can operate normally.

3. Conduct a comprehensive inspection of the security monitoring components that are simply aging once a quarter. Once the aging phenomenon is found, it should be replaced and repaired in time, such as video heads, spotlights, etc.

4. Regularly protect the security monitoring equipment for long-term operation once every two quarters. For example, the monitoring host will generate more heat during long-term operation. Once the electric fan is faulty, it will affect the heat removal and avoid the abnormal operation of the monitoring host.

5. Monitor the operation status of the security monitoring system equipment, analyze the operation status, and discover and eliminate faults in time

6. According to the situation that the user's monitoring and alarm system often presents, it may be possible to timely propose daily protection and daily use advice.

long distance service

Regarding the temporary application, operation or other non-faulty simple problems, you can directly contact the service engineer by telephone to seek the solution, operation method and technical guidance of the problem.

On-site service

During the maintenance period, all equipment of the monitoring and alarm system (such as monitoring host, camera, decoder, alarm host, double-detection detector, sound and light alarm, etc.) are damaged under normal use, and are responsible for replacement, equipment and accessories. Depending on the maintenance method, the designated party in the maintenance contract shall undertake it. After repairing, state the problem status and processing results to the user and submit a repair statement, which will be signed by the user and kept for record.

Problems in the use of equipment in the process of using the equipment should be explained clearly and guided for correct use, and rationalized propositions should be put forward.